What does it mean to be a LEGO Certified Professional (LCP)?

It means that I get to have a lot of fun working with some of the best brands in the world – LEGO being at the top of that list. It’s hard work, obviously. As a business owner, I don’t spend all my time creating. There are operational and logistical sides to the business that I manage. We have a team of 41 people at Bright Bricks. The builds we create are massive. It takes a team of people to see a project through to completion but it really is such fun.

Each Christmas, I work with LEGO on a special holiday project. My first major project with LEGO was a massive Christmas tree, complete with working lights. It’s built from over 600,000 bricks and 1000 LEGO ornaments. I love watching people’s faces when they see this massive structure for the first time. It’s incredibly rewarding work.

What other brands have you worked with through Bright Bricks and what have you designed?

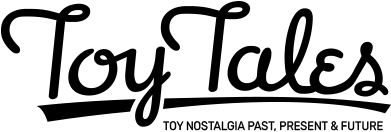

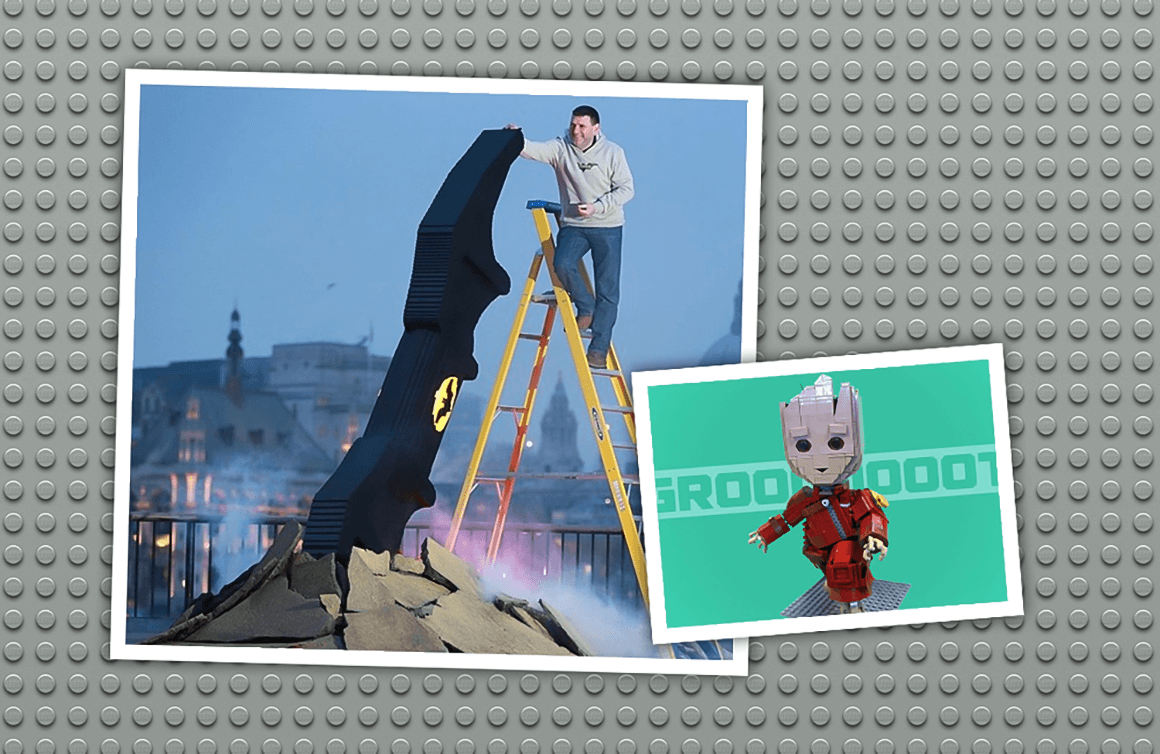

We’ve had the good fortune of working with some of the world’s biggest brands. We’ve built a working model of a Rolls-Royce jet engine; a Batmobile for Warner Bros. for the London premier of Batman v Superman; a 2-meter long model of the Bechtel tunnel boring machine used to build the Chunnel; and a model of London’s Tower Bridge for Land Rover. The build for Land Rover is the world’s largest LEGO build. It took over five months and 5.8 million bricks. It’s a privilege to work with these companies.

Bright Bricks also creates custom builds for individuals. What does that process entail?

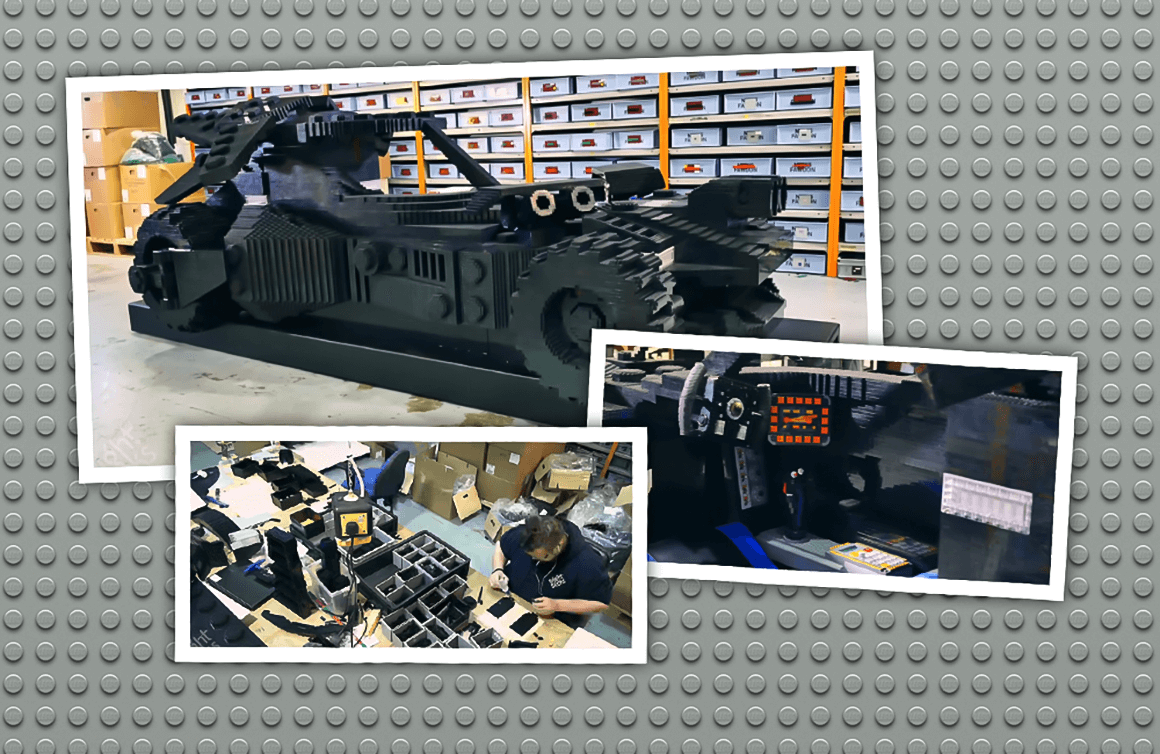

We get inquiries from around the world to build dioramas, family portraits, wedding cake toppers, small cars – things like that. Generally, these are built at Bright Bricks and shipped assembled but we recently had an individual in Dubai commission us to create a kit that is a replica of his yacht. He asked for it to be created as a kit so the family could build it together. It’s 2 meters long! I image they are having fun putting that together.

Tell me about your own LEGO collection.

I rediscovered LEGO in my early 20s. I dragged my LEGO Technic collection out of my parent’s basement and became hooked on building with LEGO again. I manage my collection carefully; otherwise, I’d have to buy a bigger house. I do make a point of purchasing the special Christmas set(s) that come out each year. They are hard to resist.

What project(s) are you working on that you’re particularly excited about?

We’re currently working with LEGO on a Christmas installation for London. I can’t reveal anything about that, of course. In mid-May, we unveil a massive model wind turbine in Liverpool. As part of LEGO’s commitment to sustainability, they are involved with a wind farm project off the coast of Liverpool and asked us to create the model as part of the project. This build could be a record-breaker; the team is really excited about it!

Editor’s Note: In 2018 Bright Bricks was acquired by Live Group, withdrew from the LEGO Certified Professional program, and moved to using non-LEGO plastic bricks.